Today’s technology is rapidly changing the way we live, the way we work and the way we produce products. There are more than 3 billion people online and since the advent of smartphones, that number is growing every day. Wholly 64% of smartphone users online shop via their smartphones.

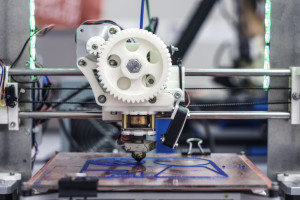

Thanks to 3D printing technology, all of that could be increasing as well.

According to 3D Printing Industry, Optomec, an Albuquerque 3D printing company, has not been as glamorous in their achievement as other 3D tech startups, but has quietly been changing the smartphone industry and many others.

Rochester is currently one of Optomec’s major customers.

“The distinction with Optomec is that we have been focused on volume manufacturing,” said Ken Vartanian of Optomec, “and how we bring additive manufacturing to volume production and mass production almost from our outset.”

Optomec recently purchased the licensing agreement of a technology developed by Sandia National Laboratories (SNL) and has since increased revenue more than 70%.

“Our solid growth in 2015 gives evidence that industrial adoption of high volume additive manufacturing is now a reality at leading corporations,” said Dave Ramahi, CEO of Optomec.

The two core technologies that Optomec has available are Aerosol Jet and LENS.

LENS stands for Laser Engineered Net Shaping and is used to produce larger components. Powder bed (Aerosol Jet) is used for more complex geometric shapes and much smaller items.

Regarding LENS: “In this case the powder is blown from nozzles,” said Ken Vartanian, experienced engineer at Optomec, “either co-azial or angled with respect to the focal point of a high powered laser.”

Vartanian stated that many of Optomec’s customers utilize their technology for all kinds of industries.

“We have customers who have implemented the LENS Print Engine in other applications,” said Vartanian. “One of our customers, the Center for Remanufacturing and Resource Recovery (C3R) at the Rochester Institute of Technology, is using LENS Print Engine technology integrated with a CNC vertical mill to repair and remanufacture military components.”

The Rochester Institute of Technology is one of the world leaders in the remanufacturing industry, which involves manufacturing damaged and worn-down in-service parts.

Vartanian added that along with some of these larger product industries, smartphones and the electronic components that make up smartphones are being mass produced all over the world thanks to Optomec.

“Lite-On Mobile Mechanical SBG is a very large electronics contract manufacturer and have operations around the world,” said Vartanian. “One of which is in Guangzhou, China. They have a number of our machines in Guangzhou operating 24/7 printing electronics onto mobile devices, such as smartphones, actually used within the smartphone.”

Vartanian continued to stress the importance of this new technology and all the added benefits that it brings. “It boils down to four components,” he added, “flexibility, speed, cost and environmental impact. All of which are important but if you can’t build it cheaper with additive manufacturing… then introducing a new manufacturing process is very difficult.”

No Comment